Las reglas que abarcan las ubicaciones húmedas y mojadas son exhaustivas y detalladas. A continuación, se muestra una versión condensada de estas reglas.

Productos de cableado impermeables, resistentes al clima y resistentes a la corrosión

Las ubicaciones húmedas y mojadas requieren de atención especial debido al impacto de la humedad en lo que respecta a la conductividad y la corrosión. Además de los requisitos para la protección ICFT para el personal, los productos de cableado utilizados en estas áreas deben cumplir con criterios de prueba específicos para garantizar la integridad de las conexiones eléctricas en entornos con mucha humedad.

Códigos y estándares

OSHA

1910.303(b)(6) y 1926.432(a)(1) – Agentes deteriorantes: a menos que se identifique su uso en el entorno operativo, ningún conductor ni equipo debe ubicarse en ubicaciones húmedas o mojadas...

2017 NFPA 70

Artículo 110.11 – Agentes deteriorantes: a menos que se identifique su uso en el entorno operativo, ningún conductor ni equipo debe ubicarse en ubicaciones húmedas o mojadas...

Artículo 406.9 – Receptáculos en ubicaciones húmedas o mojadas: todos los receptáculos de 15 A y 20 A, 125 V y 250 V para ubicaciones húmedas y mojadas son obligatorios para un tipo de...

Ubicación húmeda

Ubicaciones protegidas contra el clima y no sujetas a la saturación con agua u otros líquidos, pero sujetas a cantidades moderadas de humedad. Las ubicaciones al aire libre incluyen doseles parcialmente protegidos, pórticos abiertos y techados, y lugares parecidos. Las ubicaciones interiores incluyen áreas como sótanos, graneros e instalaciones de almacenamiento en frío.

Ubicaciones húmedas

Instalaciones subterráneas o con losas de concreto o mampostería en contacto directo con la tierra; en ubicaciones sujetas a la saturación, como áreas de lavado de vehículos y ubicaciones no protegidas del clima.

Soluciones de Leviton

Estos productos lo ayudarán a cumplir con las disposiciones especificadas por OSHA, NFPA 70E: el estándar de seguridad eléctrica en el lugar de trabajo y NFPA 70: el Código Eléctrico Nacional (National Electrical Code, NEC).

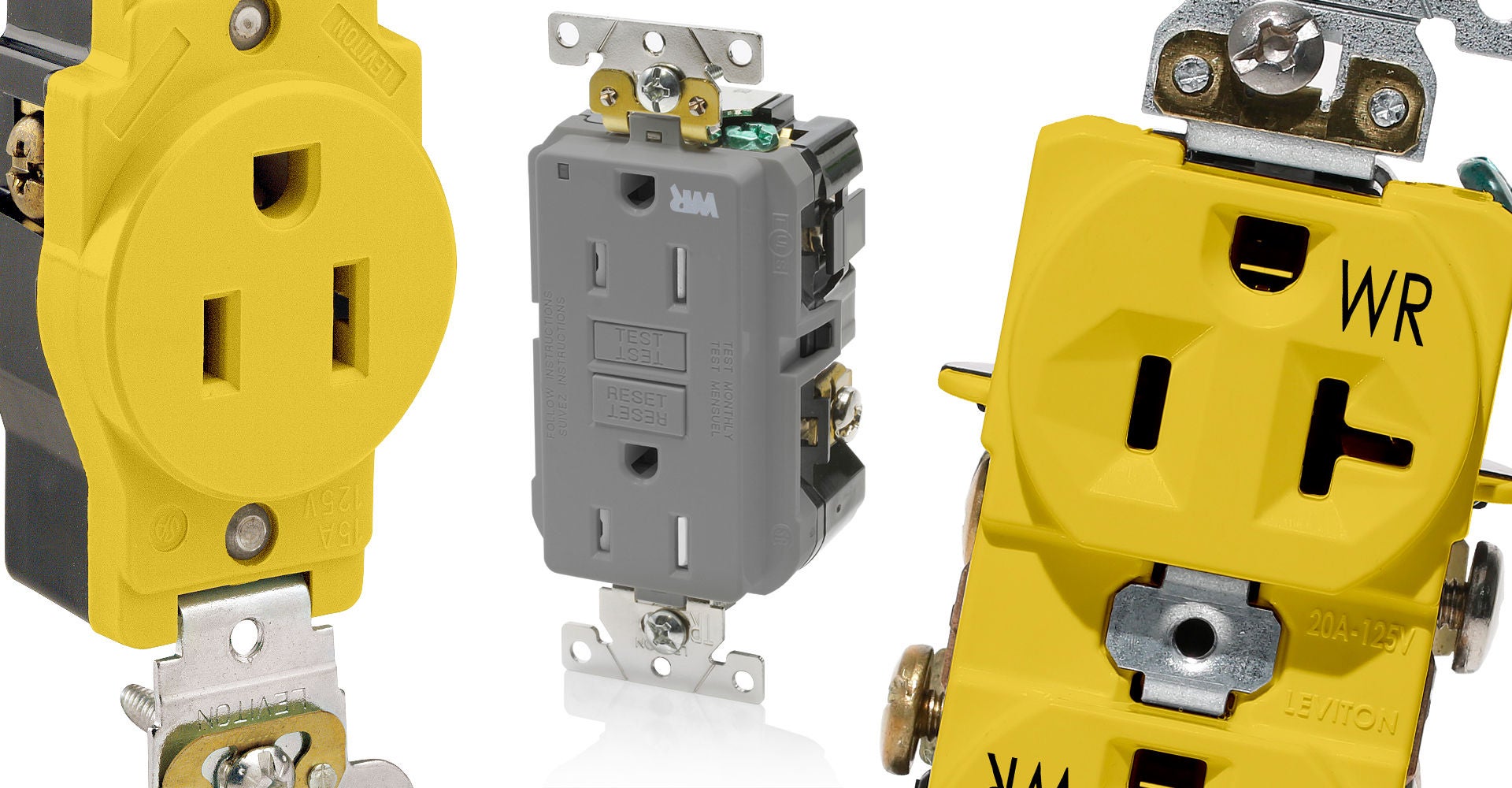

Receptáculos resistentes a la corrosión y al clima

- El rendimiento de los productos resistentes al clima está probado mediante una prueba de exposición UV, una prueba de impacto en frío y una prueba de deterioro acelerado para garantizar rendimiento fiable en condiciones húmedas y mojadas. Los productos resistentes a la corrosión también incluyen una prueba de niebla salina para simular entornos corrosivos y marinos

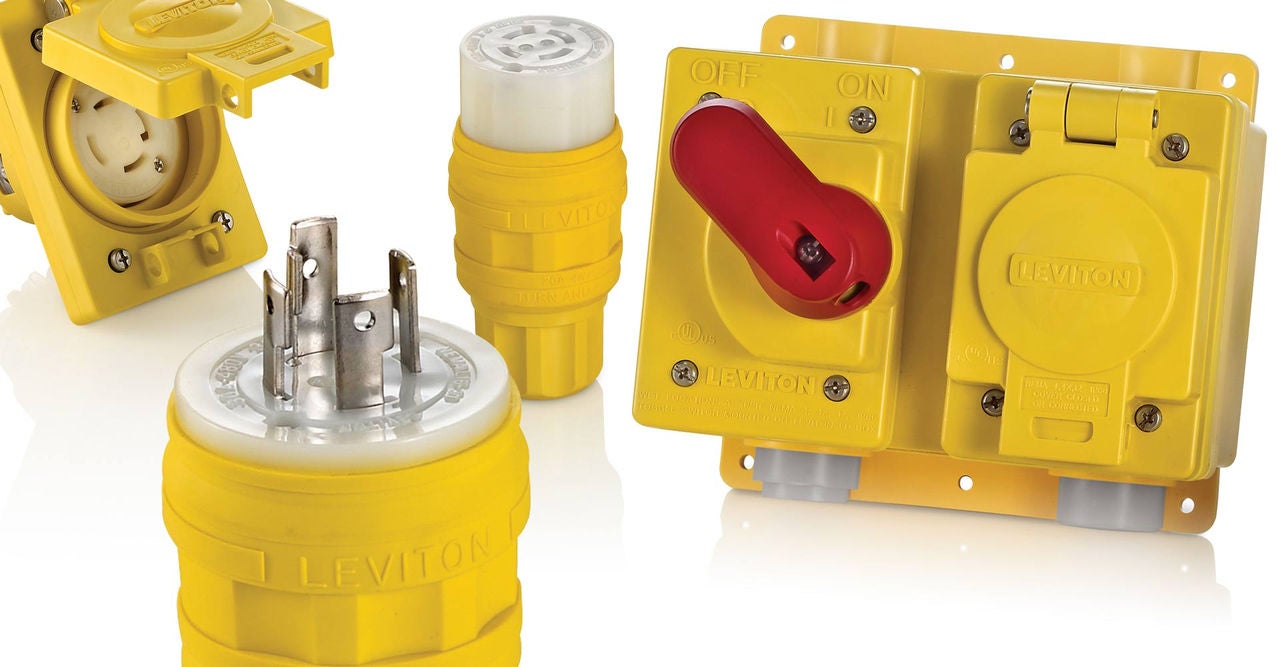

Productos impermeables Wetguard®

- Colección integral de clavijas con seguro y de hoja recta, conectores, entradas, salidas, cubiertas de productos y cajas FD.

- Impermeable y hermético al polvo; adecuado para entornos expuestos a lavados

Productos de servicio Rhino-Hide®

- Una línea sumergible, impermeable y hermética al polvo que eleva el estándar de los productos NEMA de grado industrial

- Certificación ABS para aplicaciones marinas

- Las conexiones roscadas previenen las desconexiones accidentales, incluso en entornos sujetos a vibraciones severas.

Productos de clavija y manga IEC 60309

- Clavijas, conectores, entradas, tomacorrientes e interbloqueos mecánicos para fines industriales

- Impermeable con clasificación IP67 e IP69K

- Cajas de PBT resistentes para máxima protección contra la corrosión y resistencia superior a golpes y temperaturas extremas.